About SimuTek

Engineering Excellence Since 2011

Simutek has been delivering high-quality engineering solutions since 2011. We specialize in mechanical design, advanced engineering calculations, and engineering software sales, offering tailored project and consultancy services to meet the needs of various industries.

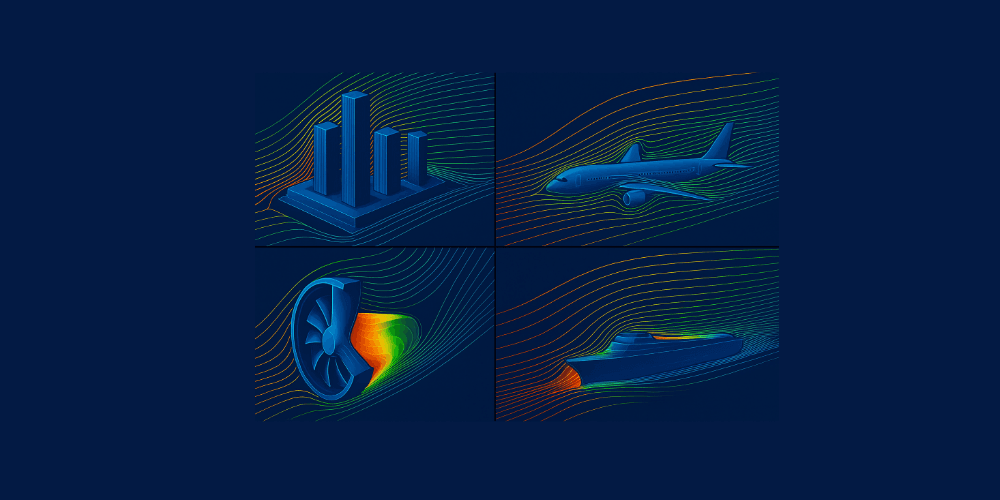

With a strong track record in defense, automotive, white goods, construction, and turbomachinery, we provide value-added solutions backed by deep expertise in structural mechanics and computational fluid dynamics (CFD).

We are also highly experienced in the energy and process industries, offering engineering services for critical systems such as gas ducts, boilers, and pressure vessels. Our designs and analyses are performed in compliance with globally recognized standards such as ASME, EN 13445, and Eurocode, ensuring the highest levels of safety, efficiency, and regulatory compliance—particularly in power generation, petrochemical, and heavy industrial applications.

Let’s build the future of engineering together.

Our Last Projects

Project Title:

Gas Treatment, Heat Recovery and Ducting System Design

Description:

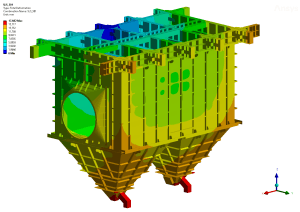

A comprehensive engineering study was carried out for an industrial facility operating under high temperatures, including gas ducts, filtration units, heat exchangers, and waste heat recovery systems.

Technical Approach:

All system components were analyzed using Finite Element Analysis (FEA) in full compliance with Eurocode standards. Structural behavior under thermal expansion, vibration, and internal pressure was thoroughly evaluated—especially for duct transitions and connection points.

Our Contribution:

Thermomechanical analysis and structural optimization

Equipment integration and safety verification

Engineering design focused on performance and durability

Project Summary:

This project evaluated pedestrian wind comfort as part of an outdoor space development in Bodrum Akyarlar.

Our Approach:

A detailed wind comfort map was created using CFD simulations, incorporating local topography and built environment. Seasonal wind conditions were modeled.

Outcomes:

Identification of zones with reduced comfort

Engineering data to support planning decisions

Evaluation based on international comfort standards

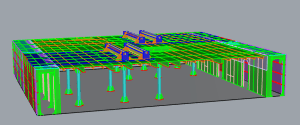

Project Scope:

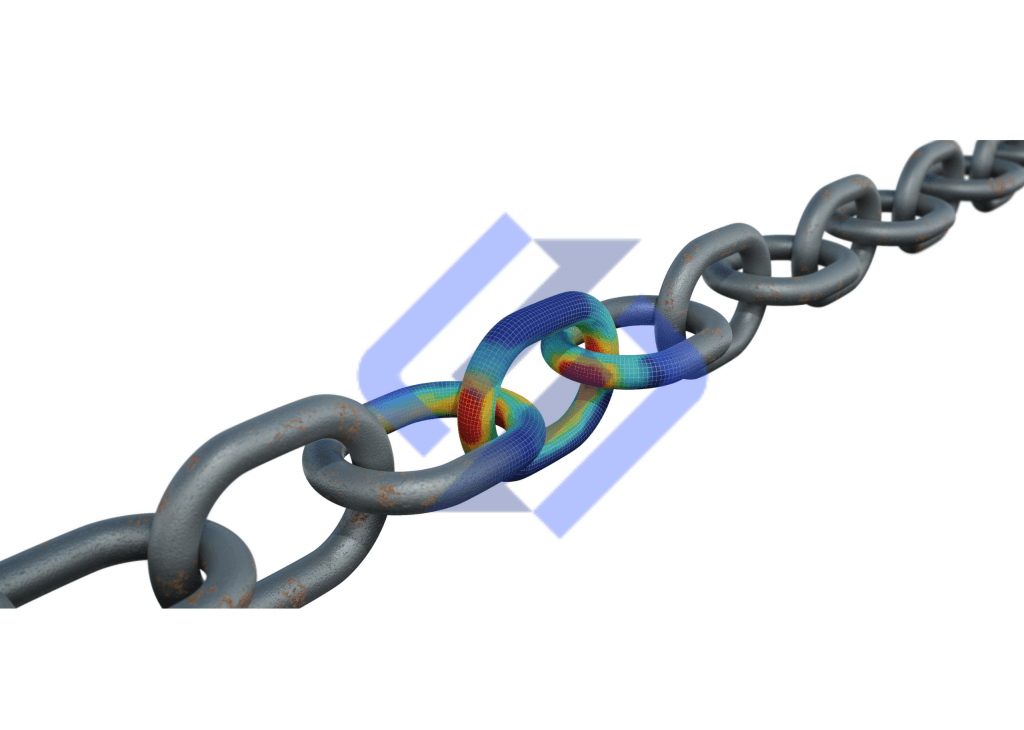

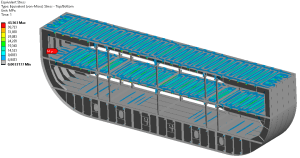

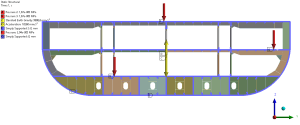

Structural modification and reinforcement of A and B Deck WEB Frames on board the M/V ORCHID to ensure full compliance with the Carriage of Livestock by Sea Regulations 2016 (Irish Maritime Transport Regulations).

Approach:

A detailed structural assessment and finite element analysis (FEA) were carried out to evaluate the load-bearing capacity of the existing frame structure under livestock-specific dynamic loads. Based on findings, localized reinforcements and geometry optimizations were designed to meet regulatory strength and safety criteria.

Deliverables:

Engineering calculations and FEA simulations

Detailed modification drawings

Compliance documentation as per Irish regulations

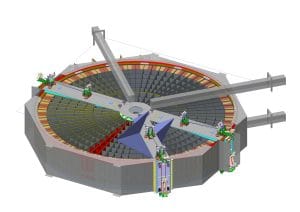

Project Summary:

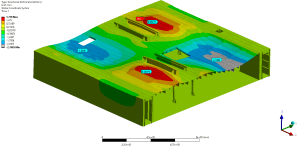

This report presents the findings regarding the stress and deformation effects induced by the applied weights on the LARS (Launch and Recovery System) platform installed on the Sancar vessel.

Technical Approach:

The Finite Element Method (FEA) was employed for numerical simulations, considering the weight distribution and platform geometry. The structural integrity was evaluated in accordance with relevant safety and performance criteria.

Outcomes:

Stress and deformation contour results

Identification of critical zones

Structural safety assessment

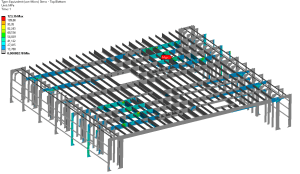

Project Summary:

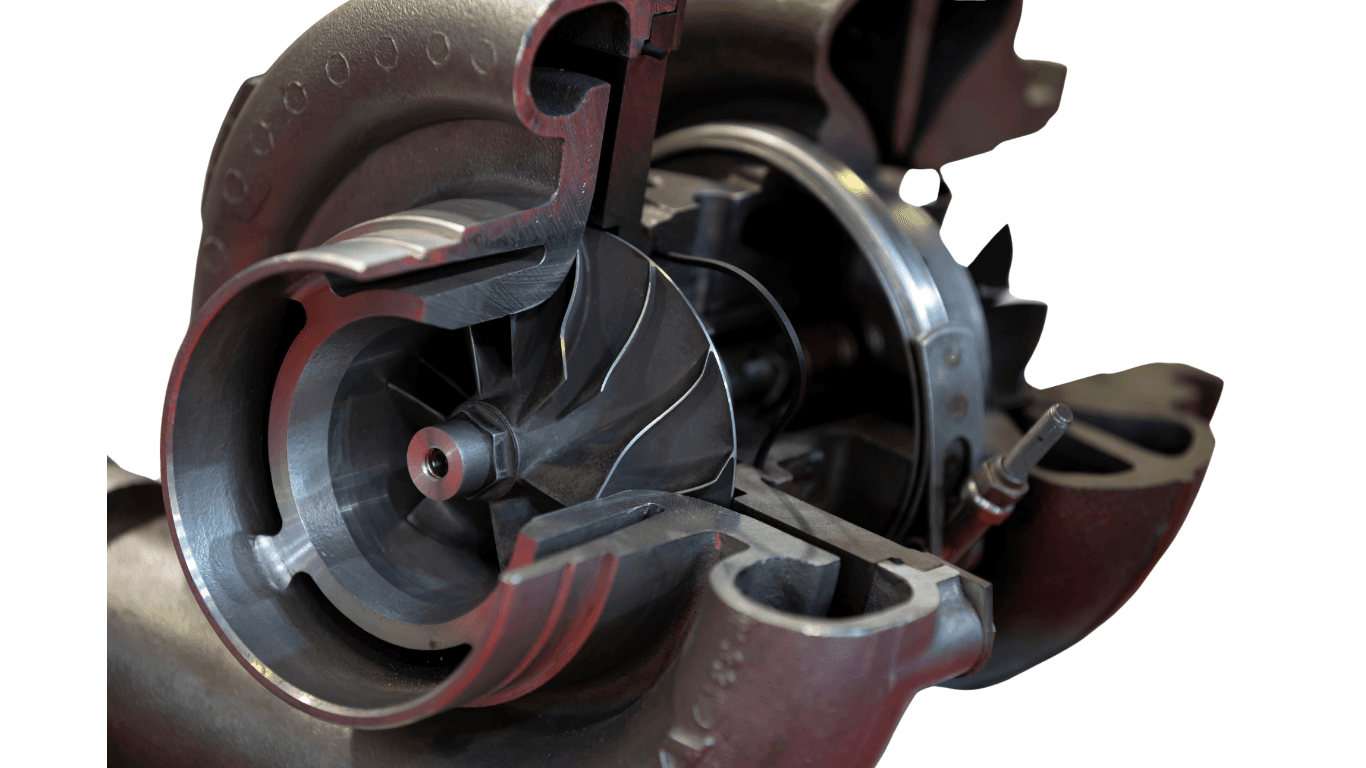

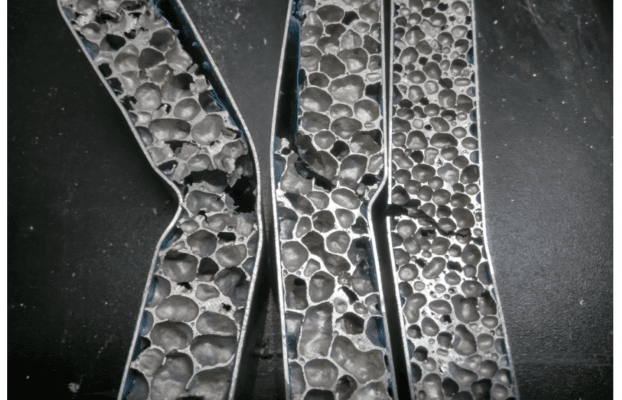

This report presents the findings of a Finite Element Analysis (FEA) and fatigue assessment conducted for the rotor region of the ISKEN Preheater project.

Technical Approach:

The rotor area was modeled under defined loading conditions to identify high-stress zones and potential fatigue initiation points. Material properties and lifecycle data were used to evaluate fatigue safety.

Outcomes:

Stress distribution and fatigue life maps

Identification of critical zones

Design optimization and safety recommendations

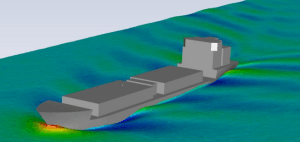

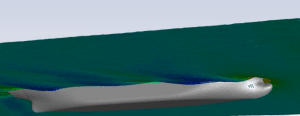

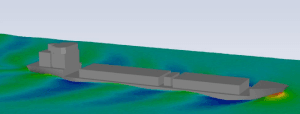

The ship model was modified by extending its length to enhance its hydrodynamic performance. The main objective was to compare the resistance characteristics of the vessel in the loaded condition before the modification (original) and after the modification (extended). The analysis focused on quantifying the resistance differences between both configurations, enabling an estimation of the power required to maintain a specified service speed. Furthermore, the results were used to assess the impact of the modification on fuel consumption, providing insights into potential improvements in operational efficiency and energy savings.

Blog

Take a look at our blog articles about our software, developments and news from us. Get to know SimuTek better.