We specialize in delivering cutting-edge mechanical design and analysis solutions tailored to your engineering challenges. Whether you’re developing a new product or optimizing an existing system, our expertise ensures robust, efficient, and innovative results.

Our Capabilities

3D CAD Modeling & Assembly Design

We use industry-standard tools to develop detailed part and assembly models with full manufacturability in mind.Finite Element Analysis (FEA)

Structural, thermal, modal, fatigue, and dynamic analyses using FEA softwares. Our FEA services help reduce material usage, increase safety margins, and identify failure points before physical prototyping.Computational Fluid Dynamics (CFD)

We simulate fluid flow, heat transfer, and pressure distributions for systems using CFD softwares. Ideal for HVAC systems, enclosures, aerodynamics, and process optimization.Mechanism Design & Motion Simulation

Dynamic simulation of linkages, gears, cams, and actuators.Material Selection & Failure Analysis

We assist in selecting suitable materials for mechanical strength, wear resistance, corrosion resistance, and thermal properties.

Industries We Serve

Automotive and Transportation

Aerospace and Defense

Energy and HVAC

Machinery and Automation

Consumer Products and Packaging

This system is an industrial robotic welding application designed to perform welding operations on profiles arranged and clamped onto a fixture. The primary goal is to automate the welding process while ensuring high precision and consistent quality.

Thanks to the fixture setup, profiles are securely positioned in the correct orientation, enabling the robot to execute accurate and repeatable welds. This automation not only enhances welding quality but also reduces human error, increases production speed, and minimizes labor costs.

This tipping conveyor is a specially designed system that enables the controlled tilting of barrels and similar cylindrical items transported via a conveyor line. The tipping operation is powered by hydraulic cylinders, ensuring smooth and reliable motion.

The conveyor itself features a roller-based structure, allowing for efficient and low-friction transport of heavy loads. Once the barrel reaches the tipping station, the hydraulic mechanism rotates it into the desired position, making downstream processes easier, safer, and faster.

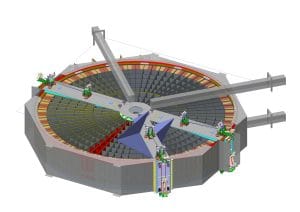

The air preheater (APH) in the İsken Power Plant is a critical heat recovery component designed to improve boiler efficiency by preheating the combustion air using flue gas. Given its continuous operation under thermal cycling, vibration, and corrosive gases, the APH is subjected to fatigue loading over time.

Fatigue Analysis

A detailed fatigue analysis is essential to evaluate the structural integrity of rotating and stationary components of the air preheater, such as:

Rotor hub and shaft

Sector plates and sealing systems

Support arms and bearing assemblies

Housing and duct connections

The following factors are considered in the fatigue analysis:

Thermal stress fluctuations due to startup and shutdown cycles

Cyclic mechanical loads from rotation and flow-induced vibration

Corrosive wear and erosion, accelerating crack initiation

Finite Element Analysis (FEA) is typically used to identify high-stress zones and predict life expectancy under realistic loading conditions.